Check valves play a crucial role in preventing backflow and protecting water pump systems. Incorrect installation can lead to significant damage or inefficiency.

In this post, we’ll discuss the best locations to install a check valve on your water pump. You'll learn why proper placement is essential for optimal performance and longevity.

What is a Check Valve and Why is it Essential for Water Pumps?

A "check valve" is a type of valve that automatically prevents backflow in a pipeline. It only allows fluid to flow in one direction, ensuring the system operates smoothly. Without it, water could flow backward, causing serious damage to equipment and disrupting the flow.

Common Types of Check Valves

Lift Check Valve: Features a disc that moves up and down, commonly used in vertical pipelines.

Swing Check Valve: Contains a hinged disc that swings to allow or block flow, ideal for larger pipes.

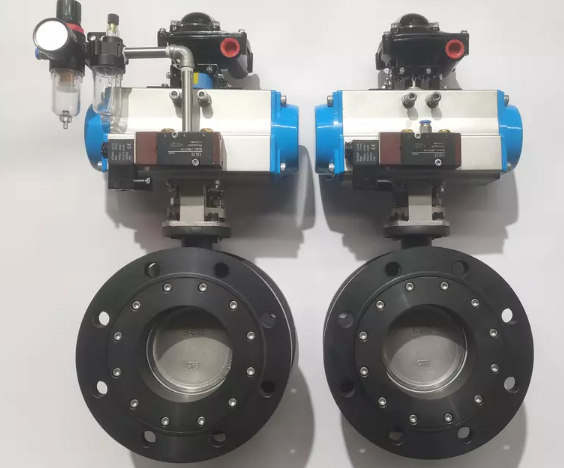

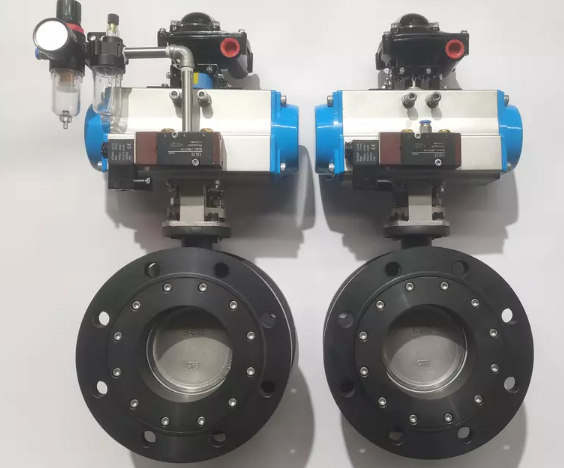

Butterfly Check Valve: A disc rotates to block reverse flow, often used in systems with limited space.

Why is a Check Valve Important in Water Pump Systems?

Preventing Damage to Equipment: Check valves prevent reverse flow that could harm pumps, pipes, and other machinery. Without them, pumps could run dry or reverse their rotation, leading to costly repairs.

Ensuring Smooth Operation: By maintaining unidirectional flow, check valves ensure the system runs efficiently. They stop water from flowing back into the pump, which helps maintain pressure and reduces wear on the pump components.

Minimizing Risks: Backflow can lead to water hammer, a dangerous pressure surge that may cause pipe bursts or damage to valves. Check valves help minimize this risk by allowing for smooth and controlled fluid flow.

Where Should You Install a Check Valve on a Water Pump?

The installation location of a check valve can greatly impact the performance and efficiency of your water pump system. Check valves can be installed either "before" or "after" the pump, each offering distinct benefits and purposes. Let's explore when and why you should install a check valve in each position.

Before the Water Pump (Suction Side)

Category | Before the Water Pump |

Purpose | Prevents Backflow | Keeps Pump Primed |

Ideal Installation | Vertical Suction Pipes (Bottom Valve) | Lower Liquid Levels |

Benefits | Prevents Dry Running | Maintains Pump Prime |

What is the purpose of installing a check valve before the pump?

Prevention of Backflow: A check valve installed before the pump stops water from flowing backward when the pump is turned off. This helps maintain system pressure.

Keeping the Pump Primed: It ensures the pump stays filled with water, preventing it from running dry, which can cause damage.

When is installation before the pump ideal?

Vertical Suction Pipes (Bottom Valve): In setups where water needs to be lifted to the pump from a lower position.

Lower Liquid Levels: When the water level is below the pump intake, a check valve at the bottom prevents water from draining back and losing the pump's prime.

Benefits and considerations of this installation method

Prevents Dry Running: Keeps water in the pump, ensuring it doesn't run dry and overheat.

Maintains Pump Prime: Keeps the pump ready for use at all times, improving system reliability.

After the Water Pump (Discharge Side)

Category | After the Pump (Discharge Side) |

Purpose | Prevents Backflow | Protects Pump |

Ideal Installation | Higher Liquid Levels | Frequent Start-Stop Cycles |

Benefits | Easy Control of Water Flow | Prevents Contamination |

What is the purpose of installing a check valve after the pump?

Preventing Backflow into the Pump: A check valve installed after the pump stops water from flowing backward when the pump is off.

Protecting the Pump from Reverse Flow: It ensures that water doesn’t flow back into the pump, which could cause damage or inefficiency.

When is installation after the pump ideal?

Higher Liquid Levels: If the water level is above the pump, a check valve after the pump helps control backflow.

Frequent Start-Stop Cycles: This is ideal for systems that turn on and off regularly, preventing water from flowing back during shutdowns.

Advantages and challenges of this installation method

Easy Control of Water Flow: Helps maintain consistent water pressure and flow.

Prevents Contamination: Stops backflow from contaminating the system, especially important in sensitive systems.

What Are the Key Considerations When Installing a Check Valve on a Water Pump?

Installing a check valve on a water pump isn't just about placement; it's about ensuring smooth operation and system efficiency. There are several factors to consider before installing the valve to avoid potential issues down the line.

Flow Direction and Positioning

How do you determine the correct flow direction for your check valve?

Identifying the Arrow: Most check valves have an arrow on the body to indicate the correct flow direction. Always install the valve in the direction the arrow points.

Proper Installation: Align the valve so that the flow direction matches the system's needs. Incorrect positioning can result in poor performance.

What happens if the check valve is installed backward?

Reversed Flow Issues: If installed backward, the check valve won’t close properly, allowing backflow. This can damage the pump, pipes, or even cause contamination in the system.

Risks to Equipment: Reversed flow can lead to system failure, higher maintenance costs, and possible equipment damage. This disrupts the pump’s ability to function effectively.

Size and Pressure Considerations

How does valve size affect installation?

Choosing the Right Valve: The size of the check valve should match the diameter of the pipe. Installing a valve that's too large or too small can lead to inefficiency and poor performance.

System Pressure: The valve must also be rated for the pressure within your system. A valve that's too weak for the pressure can fail or leak, while an oversized valve may not operate correctly.

What is the importance of cracking pressure?

Ensuring Proper Opening and Closing: The cracking pressure is the minimum pressure required to open the valve. It's crucial to choose a check valve with the right cracking pressure for your system. If the pressure is too low, it will open too soon; if it's too high, it might not open at all.

Connecting Check Valves with Other Valves

Where should check valves be installed in relation to other valves?

Isolation, Gate, and Butterfly Valves: The check valve is typically installed after isolation valves or gate valves and before control valves. This setup helps prevent backflow and protects the pump from damage.

Best Practices for Valve Placement: Place the check valve as close to the pump as possible to prevent backflow while allowing other valves to control the flow efficiently.

Should the check valve be installed before or after the control valve?

Impact on System Performance: Typically, the check valve is placed before the control valve to protect the system. This ensures that backflow doesn't enter the system and damage equipment. Installing it after the control valve can compromise the system's efficiency and may cause issues with flow regulation.

How to Install a Check Valve on a Water Pump?

| Step | Details |

1 | Choose the Right Check Valve | Size: Match valve to pipe diameter. Material: Choose durable materials like stainless steel or brass. Pressure Rating: Ensure the valve can handle system pressure. |

2 | Identify the Correct Location | Before the Pump: Prevent backflow in the suction line. After the Pump: Protect pump from reverse flow in the discharge line. System Needs: Placement based on pump operation. |

3 | Install the Check Valve | Proper Placement: Align valve securely with the pipeline. Securing the Valve: Tighten using appropriate tools. Flow Direction: Ensure arrow points in the correct direction. |

4 | Test the System | Check for Leaks: Run water and check for leaks. Verify Functionality: Ensure the valve closes and no backflow occurs when the pump is off. |

Maintenance and Troubleshooting of Check Valves on Water Pumps

Proper maintenance and quick troubleshooting can extend the life of your check valve and ensure your water pump system runs smoothly. Here are some key practices to keep your system in good shape.

Regular Check Valve Maintenance

Why is Routine Inspection Important for Check Valves?

Preventing Failures: Regular inspection ensures the valve is operating properly and can prevent system failures.

Early Detection: Routine checks help catch issues like leaks or wear before they escalate into more significant problems.

How to Inspect and Maintain Check Valves?

Cleaning: Regularly clean the valve to remove debris and sediment that can cause blockages.

Lubrication: Lubricate moving parts of the valve to reduce friction and prevent wear.

Seal Replacement: Replace seals if they become cracked or worn to maintain a tight seal and prevent leaks.

Common Issues with Check Valves

What Are the Signs of a Malfunctioning Check Valve?

Leaks: If the valve isn’t sealing correctly, water may leak from the valve or pipe connections.

Backflow: If the valve fails to close properly, water may flow backward, which can damage equipment or contaminate the system.

Failure to Close: If the valve remains open or does not close tightly, it can cause inefficient operation or system malfunctions.

How to Troubleshoot and Fix Check Valve Problems?

Debris Buildup: Clean the valve’s internal parts and remove any debris blocking the valve’s movement.

Damaged Seals: If seals are worn or damaged, replace them promptly to prevent leaks.

Improper Flow Direction: Ensure the valve is installed correctly, and check the flow direction. Reinstall if necessary to align with the system’s flow.

Conclusion

Proper check valve installation is crucial for maximizing pump efficiency. Ensure correct placement, flow direction, and valve selection. Regular inspections and timely repairs are essential to maintaining a healthy water pump system. Proper installation reduces downtime and minimizes maintenance costs, ensuring long-term performance.

FAQ

Q: What happens if a check valve is installed incorrectly?

A: Incorrect installation can lead to backflow, damaging the pump, pipes, and equipment. It also reduces system efficiency.

Q: How often should I inspect my check valve?

A: Regular inspections should be done every 6-12 months, depending on system usage, to ensure proper function and avoid failures.

Q: Can I install the check valve myself?

A: Yes, if you're familiar with basic plumbing. However, if you're unsure, it's best to consult a professional for proper installation.

Q: What are the signs my check valve needs replacement?

A: Signs include leaks, backflow, or failure to close properly, which indicate the valve is not functioning correctly.