In industrial fluid control systems, valves are essential components that regulate the flow of liquids, gases, and steam. Among the many valve types available, the cast iron wafer butterfly valve has earned a prominent place due to its practicality, cost-effectiveness, and reliability. These valves are widely used across industries such as water treatment, chemical processing, HVAC systems, and food and beverage production.

Despite their simple appearance, cast iron wafer butterfly valves play an important role in ensuring safe, efficient, and flexible operations. To fully appreciate their value, it is useful to understand their construction, features, and the many benefits they bring to industrial systems. This article provides a comprehensive look at cast iron wafer butterfly valves, explaining what they are, how they work, and why they remain one of the most widely used valve types today.

What Is a Cast Iron Wafer Butterfly Valve?

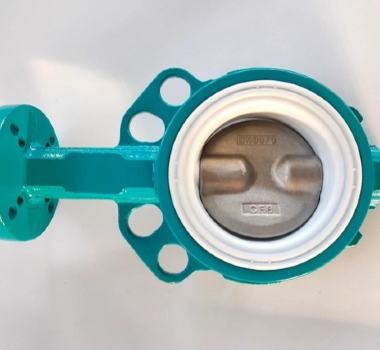

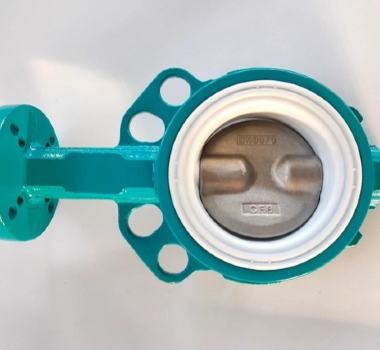

A butterfly valve is a type of quarter-turn valve that regulates the flow of a fluid by rotating a disc inside the valve body. Unlike globe or gate valves that rely on linear motion to open or close, butterfly valves rotate their disc around a central axis, allowing quick and easy operation.

The “wafer” design refers to the way the valve is installed between two flanges in a pipeline. The valve is held in place using bolts that pass through the flanges and the valve body. Wafer-style butterfly valves are compact, lightweight, and designed to prevent backflow in systems where flow needs to be shut off or controlled.

The cast iron material used in these valves provides strength, durability, and resistance to wear. Cast iron has been used in valve manufacturing for decades because of its excellent mechanical properties and cost-effectiveness, making it a reliable choice for a wide range of applications.

Key Features of Cast Iron Wafer Butterfly Valves

1. Compact and Lightweight Design

One of the most notable features of wafer butterfly valves is their slim, compact structure. Compared to gate or ball valves of the same size, they are lighter and easier to install. This makes them especially attractive in applications where space is limited or where the system design favors low-weight components.

2. Quick Quarter-Turn Operation

Butterfly valves are operated with just a quarter turn—90 degrees—of the handle or actuator. This design allows for fast opening and closing, which is particularly useful in emergency situations where flow must be stopped immediately.

3. Versatile Flow Control

The disc inside a butterfly valve can be positioned anywhere between fully open and fully closed. This allows not only for on-off control but also for throttling, giving operators flexibility to regulate flow rates with precision.

4. Wafer Connection Style

The wafer-style body is designed to fit snugly between flanges. This ensures a tight seal without requiring extra bolts or complex installation procedures. It also helps maintain pipeline alignment.

5. Wide Range of Sizes

Cast iron wafer butterfly valves are available in a variety of diameters, from small sizes suitable for residential or light commercial applications to large diameters for industrial pipelines. This adaptability makes them suitable for diverse systems.

6. Compatibility with Actuators

While many butterfly valves are manually operated with a lever handle or gearbox, they can also be fitted with pneumatic or electric actuators. This makes them easy to integrate into automated systems.

7. Cost-Effective Material

Cast iron provides a balance between strength and affordability. While it may not offer the same corrosion resistance as stainless steel, it performs well in many water-based and low-pressure applications, keeping costs manageable.

Benefits of Cast Iron Wafer Butterfly Valves

1. Easy Installation and Maintenance

Because wafer butterfly valves are compact and require fewer bolts compared to other flange types, they are quicker and easier to install. Their simple design also makes them easier to maintain. In many cases, the valve seat and disc can be replaced without removing the valve body from the pipeline, reducing downtime.

2. Reliable Sealing Performance

The sealing mechanism of wafer butterfly valves typically includes an elastomer seat that presses tightly against the disc, creating a leak-proof seal. This ensures reliable shut-off even in low-pressure systems, preventing fluid loss and contamination.

3. Space-Saving Solution

In industries where space is a premium—such as on ships, in HVAC systems, or in compact manufacturing plants—the slim design of wafer butterfly valves makes them an excellent choice. They deliver effective flow control without requiring large installation space.

4. Versatility in Applications

These valves are used across multiple industries because they can handle a variety of fluids, including water, air, oil, and some chemicals. Their versatility makes them a go-to solution for engineers designing multipurpose systems.

5. Lower Operational Costs

Compared to other valve types, wafer butterfly valves typically have a lower purchase price. Combined with their durability and ease of maintenance, they reduce overall operational costs, making them a cost-efficient long-term investment.

6. Durability in Service

Cast iron construction provides good strength and wear resistance, allowing these valves to perform reliably under normal operating conditions for years. While not suitable for highly corrosive fluids, they are well-suited to water supply systems, cooling systems, and general industrial processes.

7. Energy Efficiency

Because of their streamlined disc design, butterfly valves cause less pressure drop compared to some other valve types. This means pumps do not need to work as hard to maintain flow, contributing to energy savings in large systems.

Common Applications of Cast Iron Wafer Butterfly Valves

The versatility of these valves makes them suitable for a wide range of industries and systems:

Water Treatment Plants: Used to regulate flow in pipelines carrying treated or raw water.

HVAC Systems: Control chilled or hot water flow in heating and cooling systems.

Food and Beverage Industry: Suitable for controlling water and non-corrosive fluids in processing plants.

Power Generation: Used in cooling water circuits and auxiliary systems.

Irrigation Systems: Help regulate water distribution in agricultural systems.

Marine Applications: Compact design fits well into ships where space is limited.

Limitations to Consider

While cast iron wafer butterfly valves offer many advantages, they are not perfect for every situation. Understanding their limitations helps ensure they are applied correctly:

Corrosion Resistance: Cast iron is less resistant to corrosive chemicals compared to stainless steel or PVC. For highly corrosive fluids, alternative materials are recommended.

Pressure Ratings: These valves are generally suited for low to medium pressure systems. In very high-pressure applications, other valve types may be required.

Temperature Restrictions: Cast iron and elastomer seals have defined operating temperature ranges. Exceeding these limits can damage the valve.

By recognizing these limitations, engineers can make informed decisions and select the right valve for each system.

The Future of Wafer Butterfly Valves

With ongoing advances in materials and design, cast iron wafer butterfly valves are becoming even more reliable and efficient. Manufacturers are developing improved elastomer seats for better sealing performance, as well as coatings that enhance corrosion resistance. Additionally, the integration of smart actuators allows for remote monitoring and control, bringing butterfly valves into the era of Industry 4.0.

Conclusion

The cast iron wafer butterfly valve is a simple yet highly effective solution for controlling flow in a wide range of applications. Its compact size, quick operation, cost-effectiveness, and reliable sealing make it one of the most widely used valve types in industrial and commercial systems. While it may not be suitable for highly corrosive or extreme pressure conditions, it offers excellent performance in water, HVAC, and general fluid systems.

By understanding the features, benefits, and limitations of these valves, engineers and operators can make informed choices that lead to safer, more efficient, and more cost-effective operations. As technology continues to evolve, cast iron wafer butterfly valves will remain an essential component of modern fluid control systems.