Introduction

Are you tired of long installation times and high integration costs in automation systems? The solution might be simpler than you think.

In this article, we’ll explore how ball valve with high platform can reduce integration time and cost. You’ll learn how this design simplifies actuator installation, lowers material costs, and boosts system efficiency in automated settings.

What is a Ball Valve with High Platform?

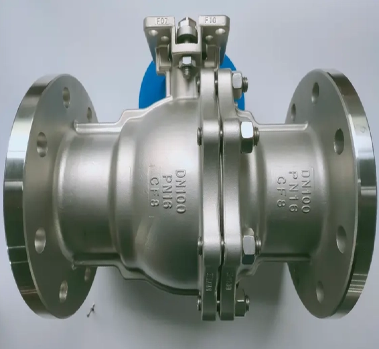

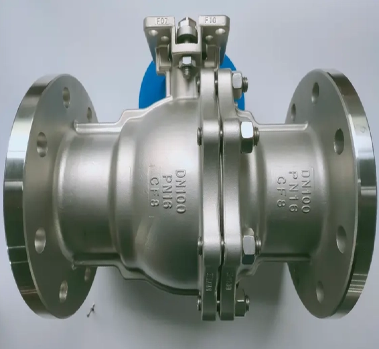

Design and Structure of High Platform Ball Valves

Ball valve with high platform is a specialized valve that integrates an actuator mounting platform directly onto the valve body. This design eliminates the need for additional mounting brackets, couplings, and complex piping, significantly reducing installation time and associated costs. By offering a direct connection for actuators, this type of valve simplifies the actuator-to-valve interaction and enhances system integration, particularly in automated settings.

The high platform design also provides additional clearance for actuators, ensuring smoother integration in confined spaces. This feature is particularly beneficial in industries that deal with space constraints, allowing for more compact and efficient installations. The high platform valve is designed for easy access and reliable operation, which is essential for industries with stringent operational requirements.

How Does a High Platform Ball Valve Work?

The ball valve with high platform operates using a spherical ball with a hole or port in its center. When the ball rotates 90 degrees, the hole aligns with the pipeline, allowing fluid to flow through. Conversely, when the ball rotates in the opposite direction, the hole is perpendicular to the flow path, shutting off the fluid completely.

The high platform design ensures that actuators can be mounted directly onto the valve, making operation smoother and more efficient. The direct mounting eliminates the need for external coupling components, reducing complexity, and improving alignment. This simplifies the system setup, reduces the chances of misalignment, and allows for faster and more precise fluid control in automation systems.

How High Platform Ball Valves Reduce Integration Time and Cost

Simplified Design and Installation

One of the most significant advantages of ball valve with high platform is the simplification it brings to the installation process. Traditional valve systems often require various additional components, such as mounting brackets, tubing, fittings, and couplings, all of which increase the complexity and duration of the installation process. These extra parts often need to be sourced, assembled, and maintained, leading to higher costs and longer installation timelines.

By eliminating the need for these additional components, ball valve with high platform significantly reduces installation time. The direct mounting feature means that actuators are easily and quickly integrated into the system without the need for extra external connections. This streamlined setup allows for faster project completion and lower labor costs, contributing to substantial savings.

Lower Material and Infrastructure Costs

In addition to reducing labor costs, the ball valve with high platform design also helps lower material expenses. The simplified design requires fewer components, meaning less material is needed for construction and installation. With fewer parts such as pipes, fittings, and brackets, there are direct savings on material costs.

Furthermore, the smaller actuators required for low-torque ball valves are more affordable than traditional larger actuators, further reducing upfront hardware and infrastructure costs. These savings on components and materials not only reduce initial costs but also lower ongoing operational expenses due to the reduced need for replacements and maintenance.

Enhanced Reliability and Maintenance Savings

The direct mounting system of the ball valve with high platform eliminates potential leak points that may arise from additional couplings and fittings. By simplifying the valve-actuator connection, the risk of leaks is minimized, improving system reliability. This also leads to fewer malfunctions, ensuring smoother operation of automated systems.

Moreover, the ball valve with high platform design simplifies maintenance. Since the number of parts is reduced, the time and effort required for repairs and replacements are minimized. Predictive maintenance capabilities, enabled by IoT integration, allow for real-time monitoring of valve performance, helping to prevent failures before they occur and reducing emergency repair costs.

Key Operational Advantages of High Platform Ball Valves

Faster Response and Improved Efficiency

The ball valve with high platform provides fast and reliable operation due to its quarter-turn design. This quick actuation allows for rapid opening and closing of the valve, which is essential for systems that require fast response times. The ability to transition from fully open to fully closed in just 90 degrees ensures that fluid flow is controlled swiftly, reducing delays and optimizing system performance.

This rapid action also contributes to higher throughput in automation systems, improving overall efficiency. The low-pressure drop provided by ball valve with high platform allows for smoother fluid movement, reducing energy consumption and enhancing operational effectiveness.

Streamlined Digital Integration

As industries increasingly embrace digitalization, the ball valve with high platform design supports the integration of IoT and other smart systems. Many modern high platform ball valves are equipped with wireless communication capabilities, allowing them to connect seamlessly with digital control systems like SCADA, BMS, or other IoT platforms.

This integration makes it easier to monitor and control valve operations remotely, providing real-time insights into system performance. The ability to collect data, analyze performance metrics, and execute remote control functions without extensive rewiring or additional infrastructure is a significant advantage for industries aiming to improve automation and system intelligence.

Industries That Benefit from High Platform Ball Valves

Oil and Gas

In the oil and gas industry, safety and efficiency are paramount, especially in high-pressure systems. Ball valve with high platform simplifies automation in these systems by reducing the number of components and ensuring a reliable, secure valve-actuator connection. The ability to streamline actuator integration not only speeds up installation but also improves overall system efficiency and reduces downtime.

The direct mounting design of these valves also contributes to better safety performance, as fewer leak points and fewer parts to maintain result in more stable operations.

Chemical Processing

Chemical processing environments often require valves that can handle harsh chemicals and extreme pressures. Ball valve with high platform is ideal for these applications due to its robustness and reliability in corrosive media. The reduced number of components reduces the risk of leaks and malfunctions, ensuring safe and efficient operation in environments where precision control of chemical flows is crucial.

The ease of maintenance and the reduced downtime afforded by the simplified design of ball valve with high platform is a significant advantage in chemical processing plants, where even small disruptions can lead to costly delays.

Water Treatment

In water treatment systems, ball valve with high platform ensures efficient fluid control, which is critical for maintaining the quality of treated water. The valve’s streamlined design makes it easy to install and maintain, reducing operational costs and improving system efficiency. Additionally, the reliability and performance of these valves in harsh conditions make them ideal for long-term use in water treatment plants.

Choosing the Right High Platform Ball Valve for Automation

Material Selection

When choosing a ball valve with high platform for automation, material selection is critical to ensure compatibility with the fluids in the system. Stainless steel (particularly SS316) is often the best choice for corrosive applications, as it offers superior resistance to chemical attack, making it ideal for harsh environments.

For applications where less corrosion resistance is required, SS304 can be used, but it may not hold up as well in highly aggressive chemicals. The material should be chosen based on the fluid composition, pressure, and temperature conditions to ensure optimal performance and longevity.

Pressure and Temperature Ratings

It’s essential to match the ball valve with high platform to your system's pressure and temperature requirements. Always verify that the valve’s pressure and temperature ratings exceed the maximum conditions of your application. This ensures that the valve can operate safely and effectively without the risk of failure due to pressure surges or temperature extremes.

Table: Comparison of Ball Valve with High Platform Material Grades

Material Grade | Best Use Case | Corrosion Resistance | Cost |

SS316 | Harsh chemicals, marine environments, high corrosion | Excellent (chlorides, acids) | Higher |

SS304 | General industrial use | Good (mildly corrosive) | Lower |

Conclusion

Ball valve with high platform provides significant benefits in reducing integration time and costs for automated systems. By simplifying actuator installation and reducing the number of components, it enhances overall efficiency and reliability.

Wuxi ideal-valve Co.,Ltd. offers high-quality ball valve with high platform solutions that improve system performance and reduce operational expenses. Their expertise ensures reliable valves that meet the needs of various industries, providing long-term value and efficiency.

FAQ

Q: What is a ball valve with high platform?

A: A ball valve with high platform integrates an actuator mounting platform directly onto the valve body, simplifying installation and improving system integration in automated settings.

Q: How does a ball valve with high platform reduce integration time?

A: The ball valve with high platform eliminates the need for extra components like brackets and couplings, streamlining actuator installation and reducing setup time.

Q: Why choose a ball valve with high platform for automation?

A: Ball valve with high platform simplifies actuator integration, reduces material costs, and enhances system efficiency, making it ideal for automated industrial systems.

Q: What industries benefit most from high platform ball valves?

A: Industries like oil & gas, chemical processing, and water treatment benefit from ball valve with high platform due to its durability, cost savings, and improved system efficiency.

Q: Are there cost-saving advantages with ball valve with high platform?

A: Yes, ball valve with high platform reduces upfront material costs, lowers labor costs, and reduces the need for large actuators, contributing to overall cost savings.