Introduction

Choosing the right valve for corrosive environments can make or break your system's efficiency. But how do you ensure that your choice will withstand the harshest conditions?

In this article, we will explore the key factors to consider when selecting a ball valve with high platform for corrosive environments. You will learn about material grades, sealing options, pressure ratings, and how to ensure the right fit for your specific application.

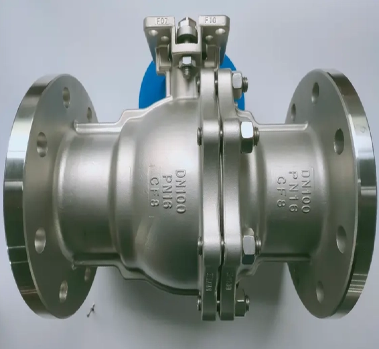

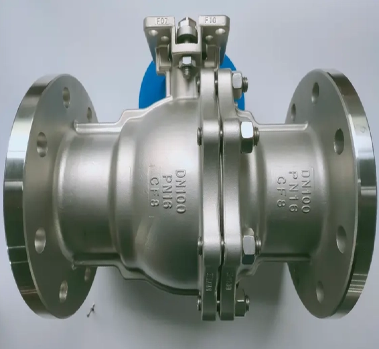

What Makes Stainless Steel High Platform Ball Valves Ideal for Corrosive Environments?

Corrosion Resistance in Stainless Steel

Stainless steel, particularly grades like SS316 and SS304, is chosen for its superior resistance to corrosion in challenging environments. The key factor in their resistance lies in the material's ability to withstand the destructive effects of harsh chemicals, high temperatures, and aggressive media.

SS316, with its molybdenum content, provides superior resistance to chloride environments, making it ideal for marine applications or industries that deal with strong acids like sulfuric acid. On the other hand, SS304 is suitable for environments with mild corrosion but may not hold up as well in more aggressive chemicals.

Choosing the right material grade is critical to ensure longevity and prevent valve degradation.

The Role of High Platform Design

The high platform design of ball valves provides extra clearance, making them more suitable for environments where insulation or easier actuator operation is needed. This design is particularly important in corrosive environments, where the ability to easily access and maintain the valve is crucial.

The high platform design allows for simpler actuator installation and integration, improving the overall efficiency of automated systems. It ensures stable valve operation while reducing potential risks related to misalignment or inadequate mounting in challenging environments.

Key Factors to Consider When Choosing a Ball Valve with High Platform for Corrosive Environments

Material Selection (316 vs 304 Stainless Steel)

When selecting a ball valve with high platform for corrosive environments, material selection is crucial. The two most commonly used materials for these valves are SS316 and SS304.

● SS316 is highly resistant to corrosion, particularly in saltwater and chemical environments. It’s the preferred choice for harsh chemical applications or marine environments.

● SS304, while less resistant to aggressive chemicals, is still a strong choice for general industrial applications that don’t involve heavy corrosion.

Here’s a quick comparison of the two stainless steel grades:

Material Grade | Best Use Case | Corrosion Resistance | Cost |

SS316 | Harsh chemicals, marine environments, high corrosion | Excellent (chlorides, acids) | Higher |

SS304 | General industrial use | Good (mildly corrosive) | Lower |

Seals and Seat Materials

The seals and seats in the valve must be chosen carefully based on the fluid being controlled. Materials like PTFE (Teflon), FKM (Viton), and FFKM (Perfluoroelastomers) are widely used in ball valves with high platform due to their excellent chemical resistance.

● PTFE is ideal for handling most chemicals and provides excellent sealing in low to medium temperatures.

● FKM is used when higher temperature resistance is needed and is commonly used in industries dealing with oils and fuels.

● FFKM is the highest-performing material for aggressive chemical environments, offering the best resistance to corrosive media.

Choosing the correct seal and seat material ensures the valve operates efficiently without leakage, even under harsh conditions.

Pressure and Temperature Ratings

A critical factor in valve selection is ensuring that the ball valve with high platform meets the pressure and temperature requirements of your application. Make sure to check the valve’s pressure-temperature (P-T) ratings to verify that they exceed your system’s operating conditions.

Choosing a valve with appropriate P-T ratings is essential for maintaining safety and reliability. Overlooking this can result in valve failure or reduced service life, especially in high-pressure or high-temperature applications like chemical reactors or steam pipelines.

Media Compatibility

It is crucial to verify that the ball valve with high platform is compatible with the specific corrosive media used in your system. Different chemicals react differently with materials, so understanding the media's composition is key.

Consult compatibility charts to determine which materials, such as SS316, PTFE, or FKM, will withstand your system’s specific chemicals, like acids, ketones, or esters. Compatibility ensures the valve’s longevity and prevents leaks or failures caused by material degradation.

Advantages of High Platform Ball Valves in Corrosive Environments

Enhanced Durability and Longevity

Ball valve with high platform is designed to offer superior durability in corrosive environments. The materials used in these valves, especially SS316, ensure a long service life, even when exposed to harsh chemicals, high pressure, and temperature extremes.

The high platform design reduces wear and tear by providing extra clearance, preventing stress on components, and allowing for easier actuator installation and operation.

Simplified Maintenance and Replacement

A major benefit of ball valve with high platform is the ease of maintenance. The integrated design simplifies the disassembly process, allowing for faster repairs and parts replacement without removing the entire valve from the pipeline. This feature is particularly valuable in industries where downtime can result in significant losses.

By eliminating complex mounting structures and enabling straightforward access to the valve components, maintenance can be performed quickly, ensuring minimal disruption to operations.

Increased Safety and Reliability

In corrosive environments, leaks and valve failures can be catastrophic. Ball valve with high platform offers secure sealing, ensuring that the valve remains leak-free, even in high-pressure applications. The design also minimizes the risk of misalignment or failure, contributing to a safer operational environment.

The ability to integrate actuators directly onto the valve further ensures consistent and predictable operation, which is essential for maintaining safety and reliability in critical applications.

How to Match a Ball Valve with High Platform to Your Specific Corrosive Application

Matching Valve Material to Specific Chemicals

When selecting a ball valve with high platform for a corrosive environment, matching the valve material to the specific chemicals in your system is paramount. For example, Hastelloy is a high-performance material ideal for handling concentrated acids, while polypropylene (PP) is suitable for weaker chemicals but not for high temperatures or pressures.

Here’s a quick guide on material compatibility:

Chemical Type | Recommended Valve Material | Example Applications |

Sulfuric Acid | SS316, Hastelloy, PTFE seals | Chemical processing, refineries |

Hydrochloric Acid | PVDF, PTFE | Water treatment, metal cleaning |

Chlorine | Hastelloy, Titanium, PVC | Chemical processing, swimming pools |

Alcohols & Ketones | Stainless Steel, PTFE | Pharmaceutical, food processing |

Choosing the Right Size and Design for Your System

The size of the ball valve with high platform must be selected based on pipe diameter and flow requirements. A full port valve is ideal for systems requiring maximum flow with minimal pressure loss. For smaller systems, reduced port valves offer a balance between cost and flow control.

Additionally, the valve design plays a key role in its performance. Trunnion-mounted valves are more suitable for large diameters and high pressures, while the high platform design ensures easy actuator installation and better clearance for operation.

Certifications and Quality Assurance in Stainless Steel Ball Valves

Industry Standards and Compliance

When selecting ball valve with high platform, ensure that it complies with relevant industry standards, such as API 6D, ISO 9001, and ASME B16.34. Certification ensures that the valve meets the required safety and performance standards for corrosive environments.

Industry certifications also provide assurance that the valve has been rigorously tested for durability, pressure resistance, and sealing capability, which is critical for ensuring reliable operation in harsh conditions.

Material and Performance Testing

To guarantee the quality of the valve, request Mill Test Reports (MTRs) that confirm the material grade and performance specifications. These reports verify the quality of stainless steel, ensuring that it meets the required standards for corrosion resistance and durability.

Manufacturers should provide detailed testing documentation, such as pressure tests, temperature tests, and chemical compatibility reports, to verify that the valve is suitable for your specific application.

Conclusion

Selecting the right ball valve with high platform is essential for ensuring performance and safety in corrosive environments. By considering material grades, sealing materials, pressure ratings, and design features, you can choose a valve that meets your specific needs.

Wuxi ideal-valve Co.,Ltd. offers high-quality ball valve with high platform solutions designed for durability and reliability in demanding applications. Their valves provide excellent resistance to corrosion, ensuring longevity and efficient operation in corrosive environments.

FAQ

Q: What is a ball valve with high platform?

A: A ball valve with high platform features an integrated mounting platform for actuators, simplifying installation and ensuring stability in corrosive environments.

Q: Why choose a stainless steel ball valve for corrosive environments?

A: Ball valve with high platform made from stainless steel offers excellent resistance to corrosion, making it ideal for harsh chemicals and high-pressure applications.

Q: How do I select the right size for a ball valve with high platform?

A: Ensure the valve size matches the pipe diameter and flow rate. For higher flow, choose full-port valves; for smaller systems, a reduced port may suffice.

Q: What materials are best for sealing in corrosive conditions?

A: For ball valve with high platform, seals made of PTFE, FKM, and FFKM offer excellent chemical resistance, ensuring secure sealing in corrosive environments.

Q: Are stainless steel high platform ball valves suitable for high-pressure applications?

A: Yes, ball valve with high platform in stainless steel, especially SS316, can withstand high-pressure environments, ensuring reliable operation even in extreme conditions.